BEMA Automazio Industrial Automation: Transforming Manufacturing Processes

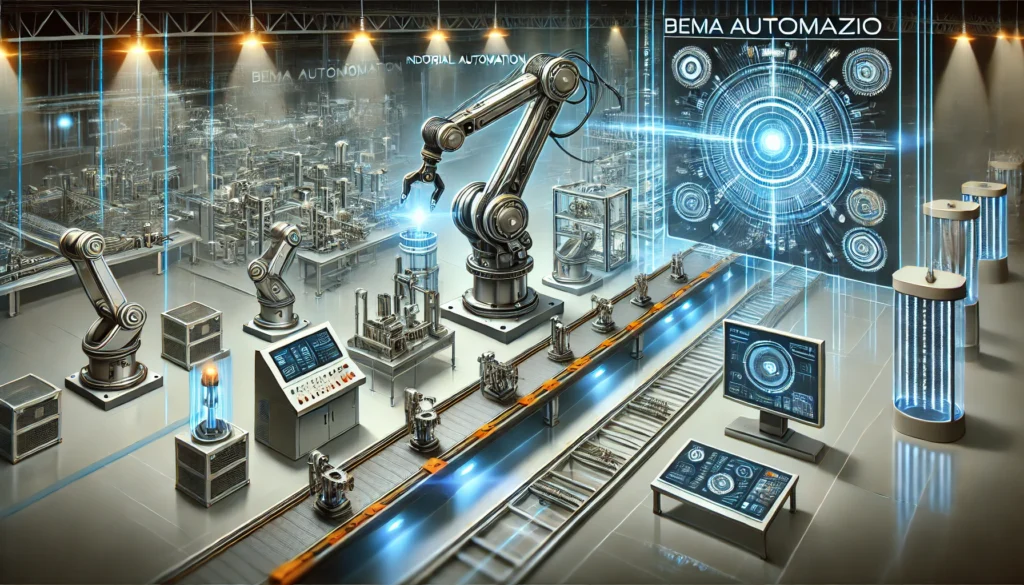

In today’s rapidly evolving manufacturing landscape, industrial automation has become a cornerstone for businesses aiming to enhance efficiency, precision, and scalability. A prominent player in this domain is BEMA Automazio, renowned for its innovative solutions that are transforming manufacturing processes across various industries.

Understanding BEMA Automazio Industrial Automation

BEMA Automazio specializes in delivering cutting-edge automation solutions tailored to meet the unique needs of modern manufacturing. Their expertise encompasses a range of products and services designed to streamline operations, reduce manual intervention, and boost overall productivity.

Key Offerings by BEMA Automazio

BEMA Automazio provides state-of-the-art industrial automation solutions designed to optimize manufacturing processes, enhance efficiency, and improve accuracy. Their innovative systems help businesses reduce costs, improve safety, and ensure seamless production operations. Below is a detailed look at BEMA Automazio’s key offerings and how they transform modern manufacturing.

1. Stretch Wrapping Systems – Silkworm

The Silkworm system is a revolutionary solution for wrapping palletized products with stretch film. This advanced automation technology ensures optimal packaging integrity while minimizing film usage, leading to significant cost savings and environmental sustainability.

Key Benefits:

✔ Reduces film consumption, lowering packaging costs.

✔ Ensures secure wrapping, protecting goods during transit.

✔ Enhances sustainability, minimizing plastic waste.

✔ Increases efficiency, reducing manual labor requirements.

This system is particularly beneficial for industries with high-volume packaging needs, such as food and beverage, logistics, and retail. By automating the wrapping process, businesses can maintain consistent packaging quality while improving operational speed.

Explore Silkworm on BEMA Automazio’s website

2. Pallet Control Automatic System – Woodpecker

The Woodpecker system is an automatic inspection and control solution for pallets, ensuring that only compliant pallets are used in manufacturing and logistics. Faulty pallets can cause serious issues, including machine malfunctions, product damage, and safety hazards. The Woodpecker system addresses these concerns by:

Key Benefits:

✔ Identifying defective pallets before they enter the production line.

✔ Enhancing safety, preventing machine breakdowns and workplace injuries.

✔ Reducing downtime, ensuring smooth operational flow.

✔ Automating pallet inspections, eliminating manual checks.

By integrating Woodpecker into their operations, manufacturers can increase efficiency, reduce costs, and improve safety standards.

Learn more about Woodpecker on BEMA Automazio’s website

3. Palletizing Systems

Palletizing is a critical process in modern manufacturing and logistics. BEMA Automazio’s palletizing systems, developed in collaboration with Elettric80, utilize anthropomorphic robots to enhance efficiency, reliability, and flexibility in managing product loads.

Key Features & Benefits:

✔ High-reliability grippers for secure product handling.

✔ Delicate product manipulation, reducing damage risks.

✔ Flexible product management, adapting to various packaging types.

✔ Compact design, maximizing floor space utilization.

✔ Reduced mechanical components, lowering maintenance costs.

✔ Automated format changes, minimizing downtime.

These robotic palletizing solutions are ideal for industries requiring high-speed, precision palletization, such as pharmaceuticals, consumer goods, and manufacturing. By eliminating manual labor, businesses can improve accuracy, efficiency, and workplace safety.

Discover BEMA Automazio’s Palletizing Systems

4. Layer Picking System

The Layer Picking System is a flexible and reliable automation solution designed to improve the handling of finished products. It enhances order fulfillment and inventory management, making warehouse operations faster and more efficient.

Key Benefits:

✔ Improves warehouse automation, reducing manual labor.

✔ Enhances picking accuracy, minimizing order errors.

✔ Optimizes storage space, making inventory management more efficient.

✔ Speeds up order processing, reducing fulfillment times.

By integrating layer picking automation, businesses can streamline logistics operations, enhance supply chain management, and increase overall efficiency.

Find out more about BEMA Automazio’s Layer Picking System

BEMA Automazio’s industrial automation solutions are transforming manufacturing by enhancing efficiency, reducing costs, improving safety, and ensuring seamless workflows. From stretch wrapping and pallet inspections to robotic palletizing and layer picking systems, their cutting-edge technologies are setting new standards in industrial automation.

Companies looking to automate manufacturing and warehouse operations can benefit greatly from BEMA Automazio’s expertise in robotic and process automation. By integrating these advanced automation solutions, businesses can boost productivity, reduce waste, and gain a competitive edge in their industry.

Would you like more details on a specific automation system? Let me know! 🚀

Benefits of Implementing BEMA Automazio’s Solutions

Integrating BEMA Automazio’s industrial automation solutions can lead to several advantages:

- Enhanced Efficiency: Automation reduces manual labor, leading to faster production cycles and increased throughput.

- Improved Accuracy: Automated systems minimize human errors, ensuring consistent product quality.

- Cost Savings: By optimizing resource utilization and reducing waste, businesses can achieve significant cost reductions.

- Scalability: Automation solutions provide the flexibility to scale operations seamlessly in response to market demands.

Comparison: Traditional Manufacturing vs. Automated Manufacturing

To illustrate the impact of automation, consider the following comparison:

| Aspect | Traditional Manufacturing | Automated Manufacturing |

|---|---|---|

| Labor Intensity | High manual labor | Minimal manual intervention |

| Production Speed | Limited by human capacity | Enhanced by continuous operation |

| Error Rate | Higher due to human factors | Significantly reduced |

| Operational Costs | Higher due to labor and waste | Lower through efficiency gains |

| Scalability | Challenging and time-consuming | Easily adjustable |

FAQs about BEMA Automazio Industrial Automation

What industries can benefit from BEMA Automazio’s solutions?

BEMA Automazio’s automation solutions are versatile and can be applied across various industries, including food, beverage, tissue, and other consumer goods sectors.

How does the Silkworm Stretch Wrapping System differ from traditional wrapping methods?

The Silkworm system offers a revolutionary approach by optimizing film usage and ensuring consistent wrapping quality, which is a significant improvement over manual or semi-automatic methods.

What is the significance of the Woodpecker Pallet Control System?

The Woodpecker system ensures that only compliant pallets are used in the manufacturing process, enhancing safety and reducing potential equipment damage.

Can BEMA’s palletizing systems handle different product types?

Yes, BEMA’s palletizing systems are designed for flexibility, allowing them to handle various product types with ease.

How do BEMA Automazio’s solutions contribute to cost savings?

By automating processes, reducing manual labor, minimizing errors, and optimizing resource utilization, BEMA’s solutions lead to significant cost savings for manufacturers.

Conclusion

BEMA Automazio Industrial Automation is at the forefront of transforming manufacturing processes through innovative automation solutions. By implementing their advanced systems, businesses can achieve higher efficiency, improved accuracy, and substantial cost savings, positioning themselves for success in the competitive manufacturing landscape.

For further insights into maximizing your business efficiency, consider reading our article:

- Partner Ecosystem Digital Marketing Manager IBM:

- Boost Your Business with an Online Marketing Bureau

- Best Call Routing for Small Business Dialics.com 2024

- Best Banks for Startups in 2024

- Customer Acquisition Cost for Startups: Proven Tips for 2024

- Wyoming LLC Taxation for Non US Residents: Best Facts 2024

- Best Banks for Startups in 2024

Our Blog on Insurance & our Best Articles:

- Does ClicRx Use Insurance? 3 Interesting Facts You Need to Know!

- Would an insurance adjuster trick you with a bank statement? 5 Red Flags to Watch!

- Does clicrx eye glasses use vision benefits insurance? 4 Things You Should Know!

- What Does Comprehensive Vehicle Insurance Cover by Moneytadka.com? 3 Essential Insights!

- How much does bar insurance cost in sequin Texas 2024? 3 Best Pricing Tips!

- AAL Insurance: Top 7 Benefits You Can’t Ignore!

- CIG Auto Insurance: 4 Reasons It’s the Best Choice in 2025!

Our Blog on Trading & our Best Articles:

- Blackbox Trading Explained: How It Works and Is It Right for You?

- Electronic Trading: How Technology is Transforming Financial Markets

- Mastering ICT Trading: Understanding Institutional Concepts and Strategies

- The Rise of AI Trading Software: Can Artificial Intelligence Beat the Market?

- Top 10 Best Futures Trading Platforms for 2025: A Complete Guide